SAFELOG AGV S3, M4, M4-C, X1 & L2 – always the right solution

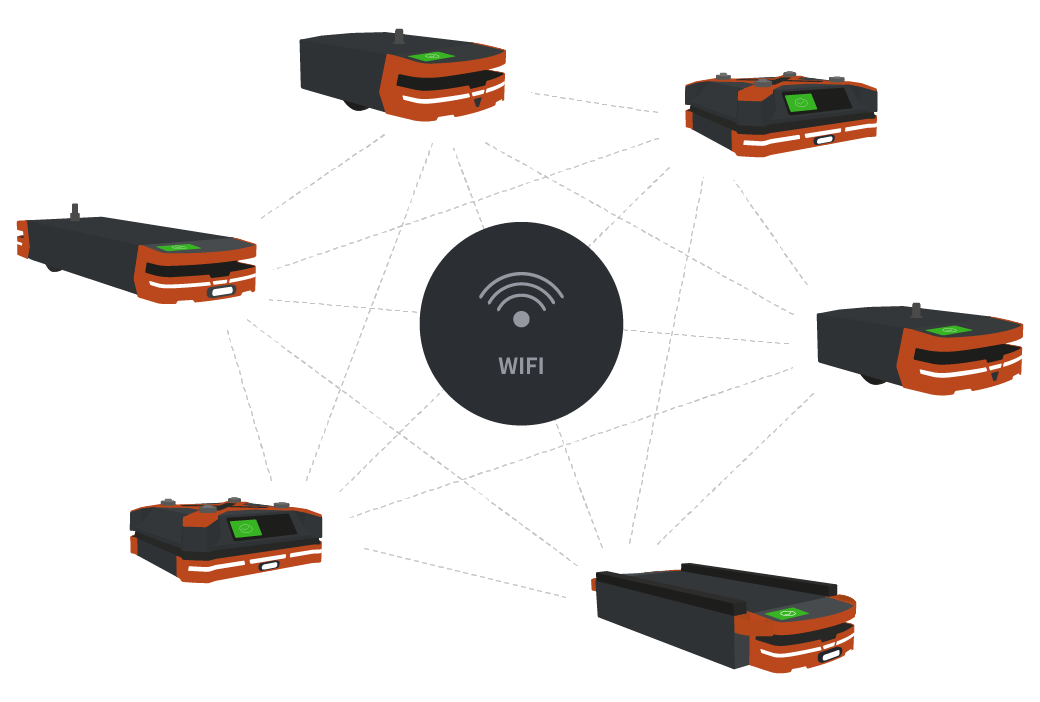

The agent-based control of the AGVs without a higher-level control center allows profitable operation even with a limited number of AGVs. SAFELOG can provide AGV fleets of several hundred vehicles using swarm intelligence. SAFELOG IntelliAgent software ensures communication between the devices over Wi-Fi. It also integrates the swarm into the surrounding production and logistics facilities. An app for mobile devices provides a system overview in real time and displays the operating status.

All SAFELOG AGV models are compatible with SAFELOG picking solutions such as the IntelliCart. From the initial planning steps to after-sales services – SAFELOG is a reliable partner every step of the way towards AGV-supported processes.

SAFELOG AGV Projects: The full program

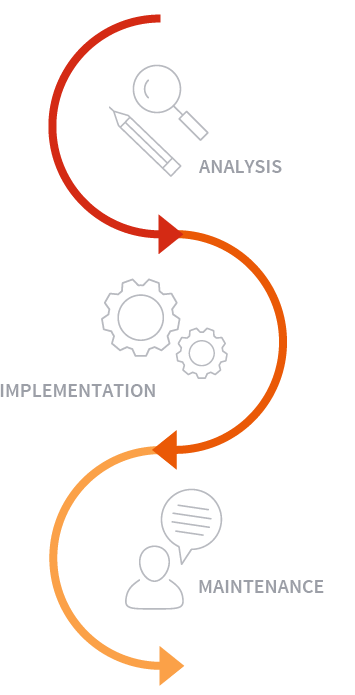

Analysis & Concept

An honest assessment of whether and how an AGV project can be implemented is second nature to SAFELOG. As a first step, we visit your site and analyze your processes. We advise you on the feasibility of your project and draw up an initial concept as a basis for discussion.

Consultation & Planning

The results of the analysis provide the foundation for the next steps. SAFELOG provides advice with regard to suitable hardware and software as well as the appropriate types of device. The connection of SAFELOG components to existing ERP, production control or warehouse management systems is also taken into account. The goal is a well thought out integrated solution based on your individual needs. With the help of the information from the interviews as well as the answers from a questionnaire, we can also offer a resilient cost calculation.

Project planning & implementation

Especially when integrating the automated goods supply into existing processes, we want to avoid long downtimes. SAFELOG manufactures all of the devices quickly and with great precision. The SAFELOG team is on site for the commissioning of the automated guided vehicles and programs their routes. The team sets up the AGV swarm in the operating environment and connects it to existing software systems.

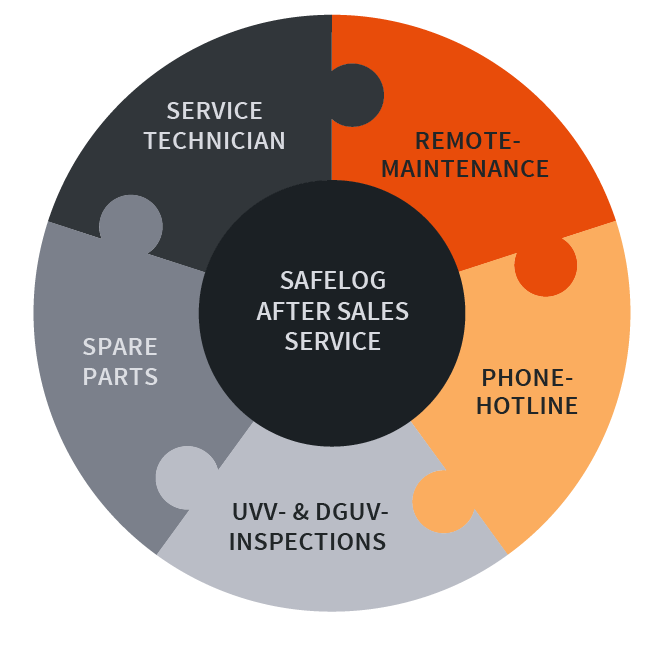

After Sales Service

For SAFELOG, commissioning is just the start of further cooperation. The smooth running of your processes is a priority for us, even after you sign off on the equipment. We are at your side as a reliable and flexible partner with a wide range of services. We will be delighted to answer any questions you may have about maintenance, service and repair.

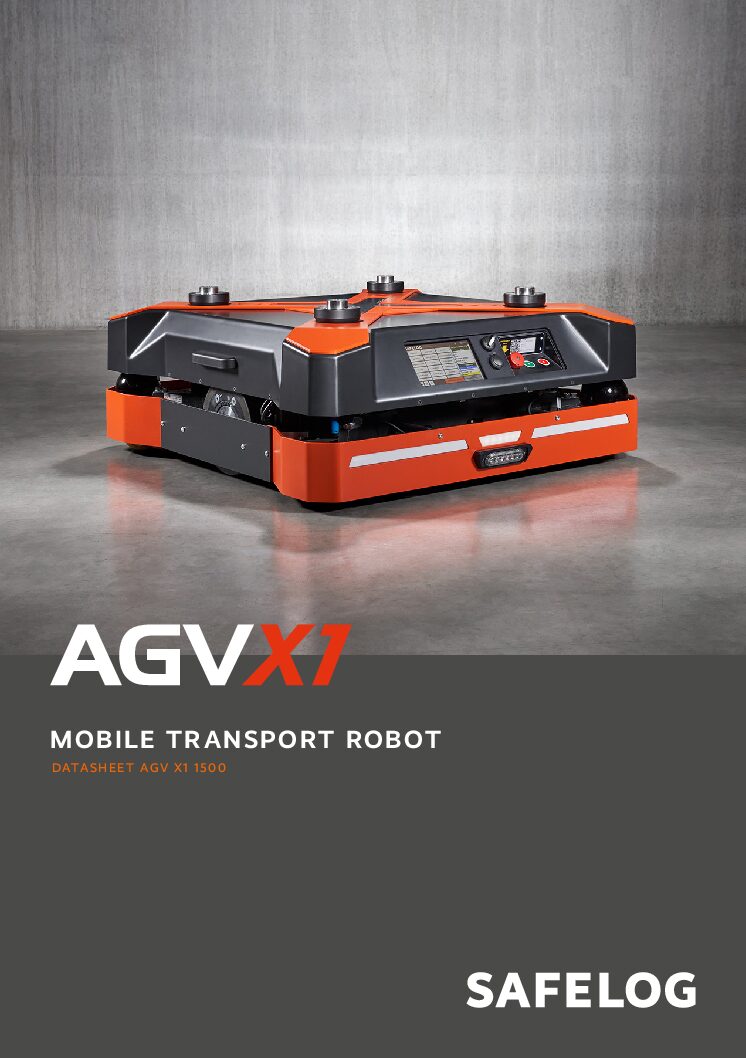

Here, the mobile robot can be used for pallet or pallet cage transport, as a goods-to-person or assembly platform. Loads of up to 1,500 kg are picked up by four lifting pins positioned at the corners of the FTF. These can be supplemented by special superstructures. The modified differential drive allows speeds between 0.02 and 1.6 m/s. Furthermore, space-saving turning on the spot is easily possible. The minimum curve radius is 100 cm. For maximum safety, the AGV X1 is equipped with a safety laser scanner in each direction of travel.

DIMENSIONS:

840 / 820 / 340 (L/W/H) in mm

TARE WEIGHT:

215 kg

SPEED:

from 0.02 up to 1.6 m/s

BATTERY CHARGING:

in-process charging using an inductive charging system

NAVIGATION: hybrid navigation using contour navigation, magnetic track, camera navigation and odometry

DISPLAY:

7“ touch display for ease of use

DIMENSIONS:

840 / 820 / 340 (L/W/H) in mm

TARE WEIGHT:

215 kg

SPEED:

from 0.02 up to 1.6 m/s

BATTERY CHARGING:

in-process charging using an inductive charging system

NAVIGATION: hybrid navigation using contour navigation, magnetic track, camera navigation and odometry

DISPLAY:

7“ touch display for ease of use

DATA SHEET AGV X1 1500 (METRIC)

DATA SHEET AGV X1 1500 (IMPERIAL)

In contrast to the previous AGV X1 1500, the new model of the X series does not pick up the load via four electric lifting pins, but via a central lifting unit. This can lift the goods up to a lifting height of 80 mm and handle loads up to a top load of 1,200 kg. The mobile transport robot is equipped with a rotating unit that allows the robot and load to rotate independently of each other. This enables the AGV X1 tt to realign the goods to be transported even in confined spaces. The Goods to Person platform is used primarily in fulfillment centers and on production lines. Shelves or pallets are particularly suitable as transport goods.

DIMENSIONS:

840 / 820 / 367 (L/W/H) in mm

TARE WEIGHT:

232 kg

SPEED:

from 0.02 up to 1.6 m/s

BATTERY CHARGING:

in-process charging using an inductive charging system

NAVIGATION: hybrid navigation using contour navigation, magnetic track, camera navigation and odometry

DISPLAY:

7“ touch display for ease of use

DIMENSIONS:

840 / 820 / 367 (L/W/H) in mm

TARE WEIGHT:

232 kg

SPEED:

from 0.02 up to 1.6 m/s

BATTERY CHARGING:

in-process charging using an inductive charging system

NAVIGATION: hybrid navigation using contour navigation, magnetic track, camera navigation and odometry

DISPLAY:

7“ touch display for ease of use

DATA SHEET AGV X1 tt (METRIC)

DATA SHEET AGV X1 (IMPERIAL)

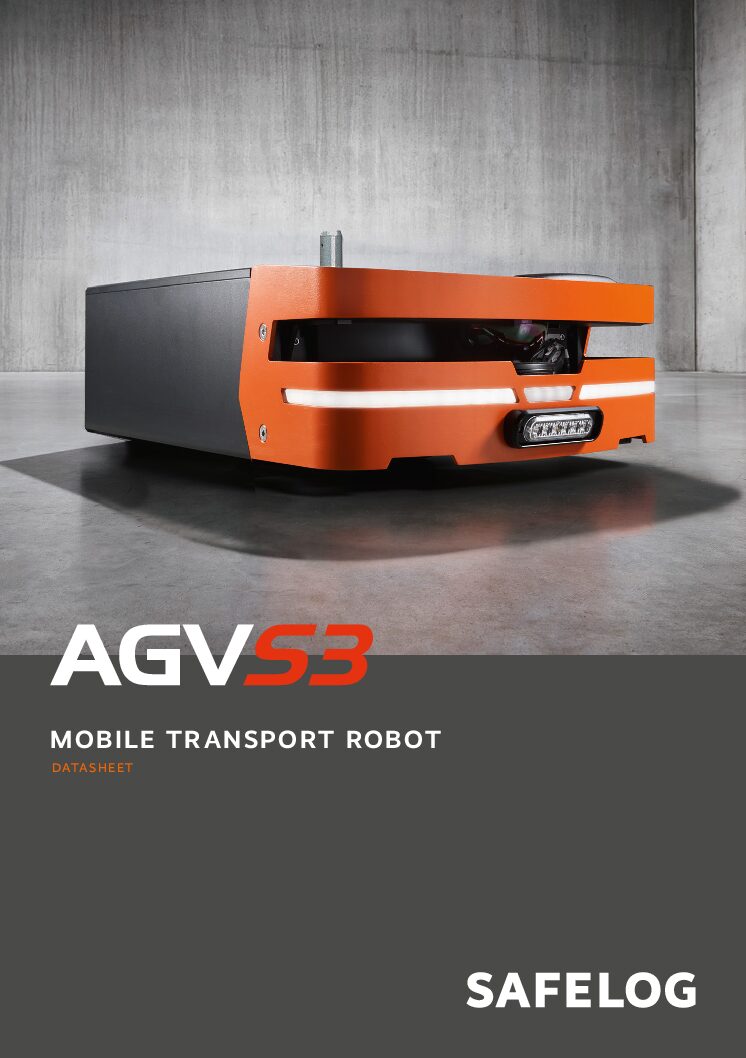

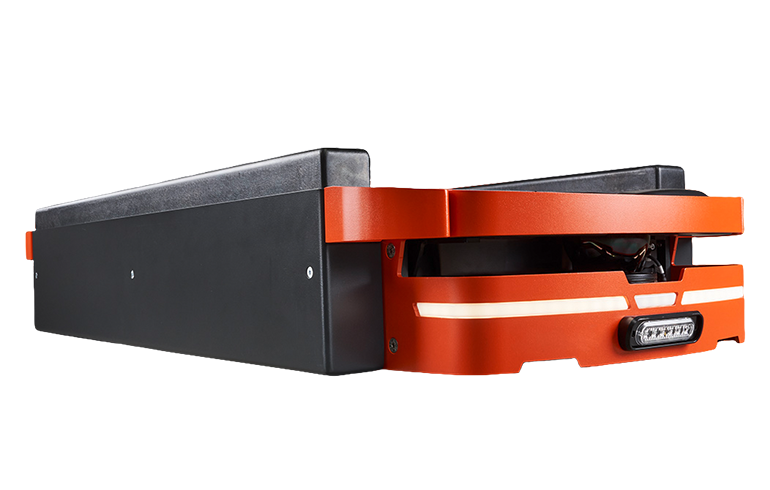

With its compact dimensions, the S3 can turn on the spot, requiring a diameter of less than 90cm. Transport jobs in confined spaces are therefore no problem. With its height of 220 mm, the mobile transport robot can drive under most of the trolleys and trailers commonly available on the market in order to couple them via snap latches. The maximum weight for towing load is 500 kg. The pick-up and release of the towed load takes place automatically via an electric lifting pin. Thanks to variable superstructures with up and down conveyor technology, the SAFELOG AGV S3 transports top loads of up to 150 kg. A laser scanner in the direction of travel with definable warning and safety zones ensures slowed travel or complete stop in the event of obstacles in the danger zone. AGV communication both with each other and with peripheral systems is via WLAN or mobile networks. Thanks to swarm intelligence, the agent-based control system of the SAFELOG AGV models IntelliAgent does not require a higher-level control station.

DIMENSIONS:

770 / 450 / 220 (L/W/H) in mm

TARE WEIGHT:

150 kg

SPEED:

from 0.02 up to 1.6 m/s

BATTERY CHARGING:

in-process charging using an inductive charging system

NAVIGATION: hybrid navigation using contour navigation, magnetic track, camera navigation and odometry

DISPLAY:

7“ touch display for ease of use

DIMENSIONS:

770 / 450 / 220 (L/W/H) in mm

TARE WEIGHT:

150 kg

SPEED:

from 0.02 up to 1.6 m/s

BATTERY CHARGING:

in-process charging using an inductive charging system

NAVIGATION: hybrid navigation using contour navigation, magnetic track, camera navigation and odometry

DISPLAY:

7“ touch display for ease of use

DATA SHEET AGV S3 (METRIC)

DATA SHEET AGV S3 (IMPERIAL)

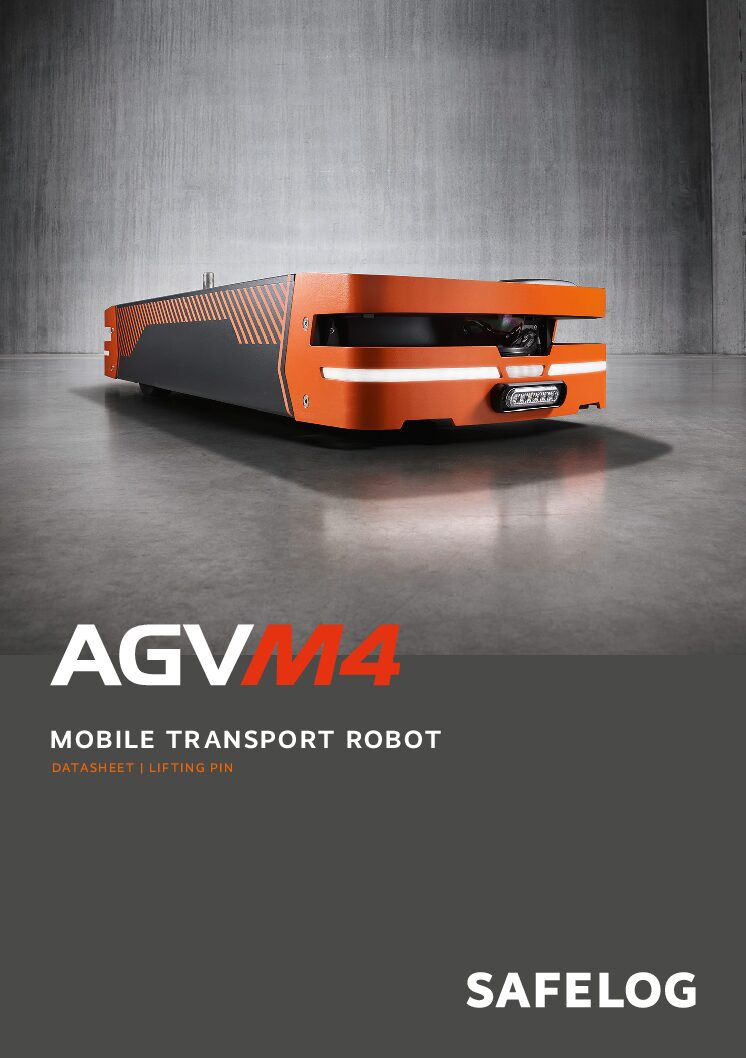

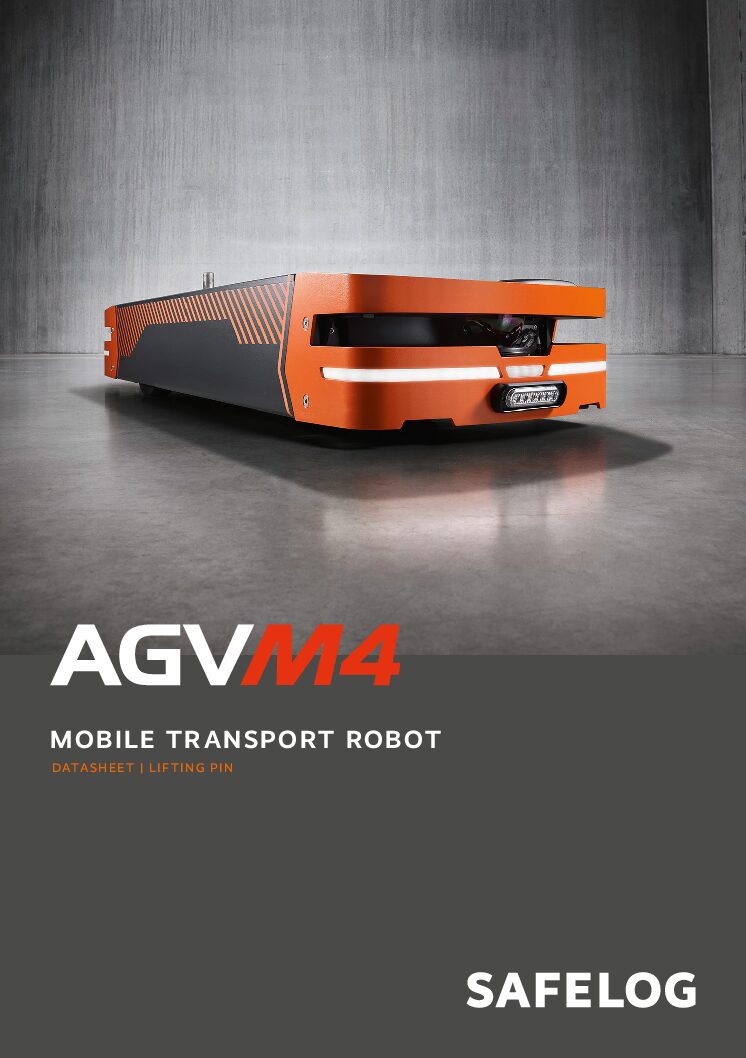

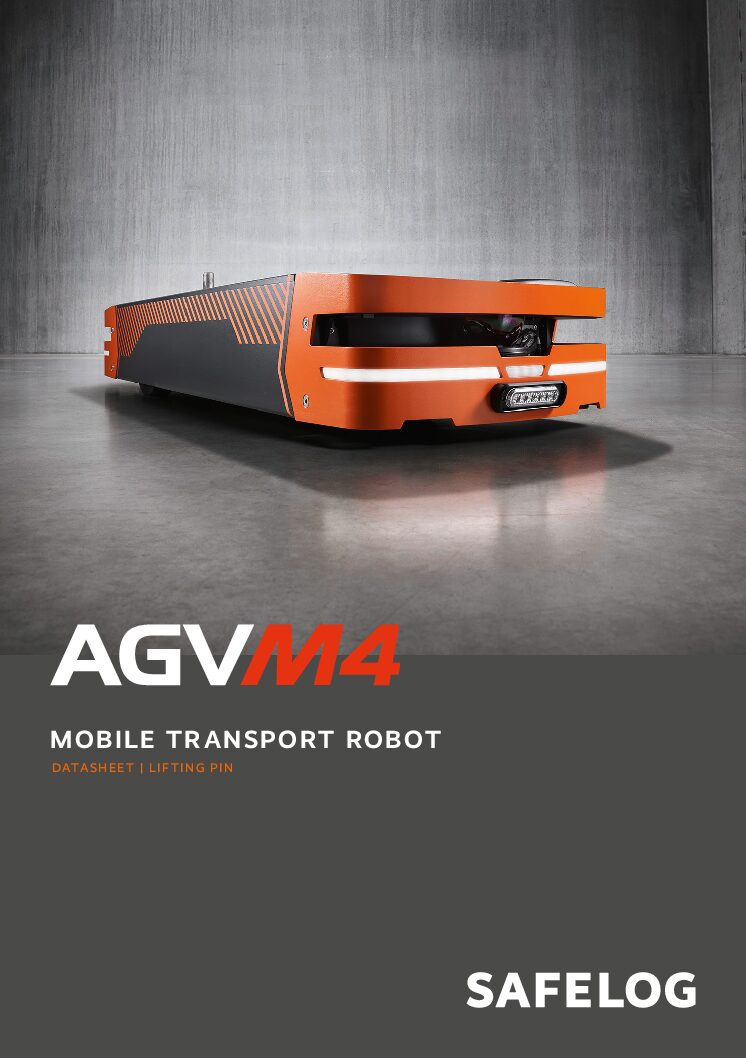

It can be automatically coupled and uncoupled through a system of lifting bolts and snap latches that is combined with an RFID reader used to identify material supply trolleys. The maximum towing load is 1,500 kg. In the standard version, the AGV M4 can handle a top load of 300 kg. The sturdy steel chassis has an IP54 rating so it is protected against dust and water splashes. The newly developed brushless DC motor achieves a higher starting torque. The AGV M4 is capable of speeds ranging from 0.02 m/s to 1.6 m/s. By means of intelligent, agent-based control, the AGV communicates both with other transport robots and with peripheral systems. Thanks to swarm intelligence, a higher-level control centre is not necessary. However, the required interfaces for a control centre connection, such as VDA 5050, are available.

DIMENSIONS:

1460 / 450 / 220 (L/W/H) in mm

TARE WEIGHT:

235 kg

SPEED:

from 0.02 up to 1.6 m/s

BATTERY CHARGING:

in-process charging using an inductive charging system (optional sliding contacts on the floor)

NAVIGATION: hybrid navigation using contour navigation, magnetic track, camera navigation and odometry

DISPLAY:

7“ touch display for ease of use

DIMENSIONS:

1460 / 450 / 220 (L/W/H) in mm

TARE WEIGHT:

235 kg

SPEED:

from 0.02 up to 1.6 m/s

BATTERY CHARGING:

in-process charging using an inductive charging system (optional sliding contacts on the floor)

NAVIGATION: hybrid navigation using contour navigation, magnetic track, camera navigation and odometry

DISPLAY:

7“ touch display for ease of use

DATA SHEET AGV M4 (METRIC)

DATA SHEET AGV M4 (IMPERIAL)

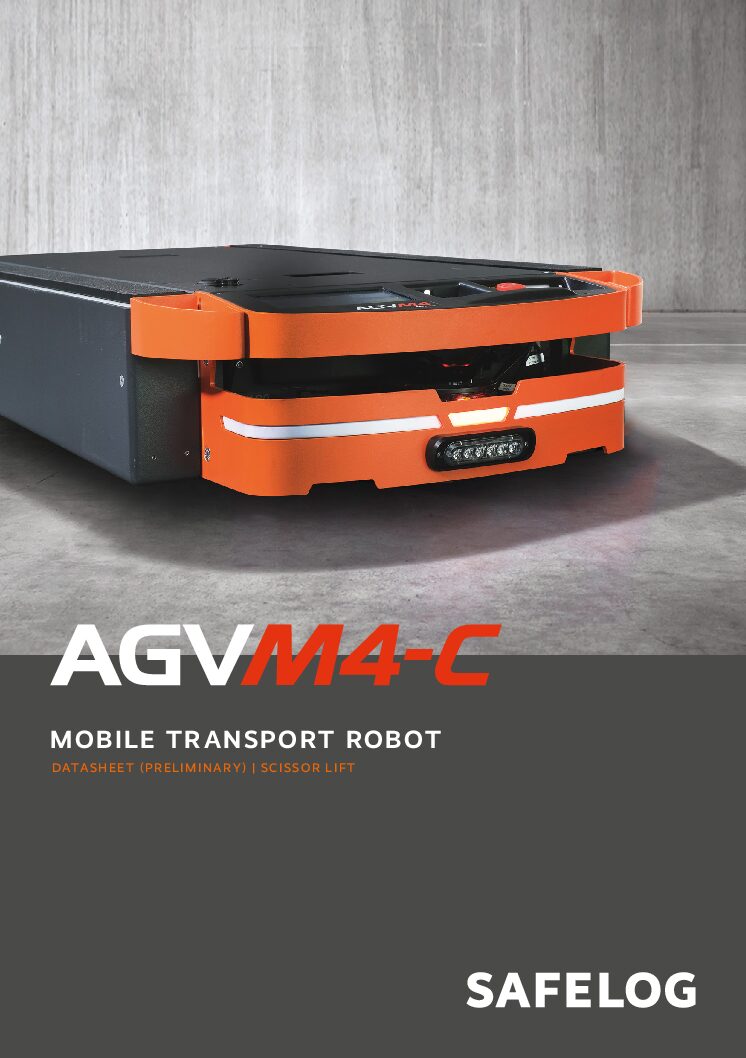

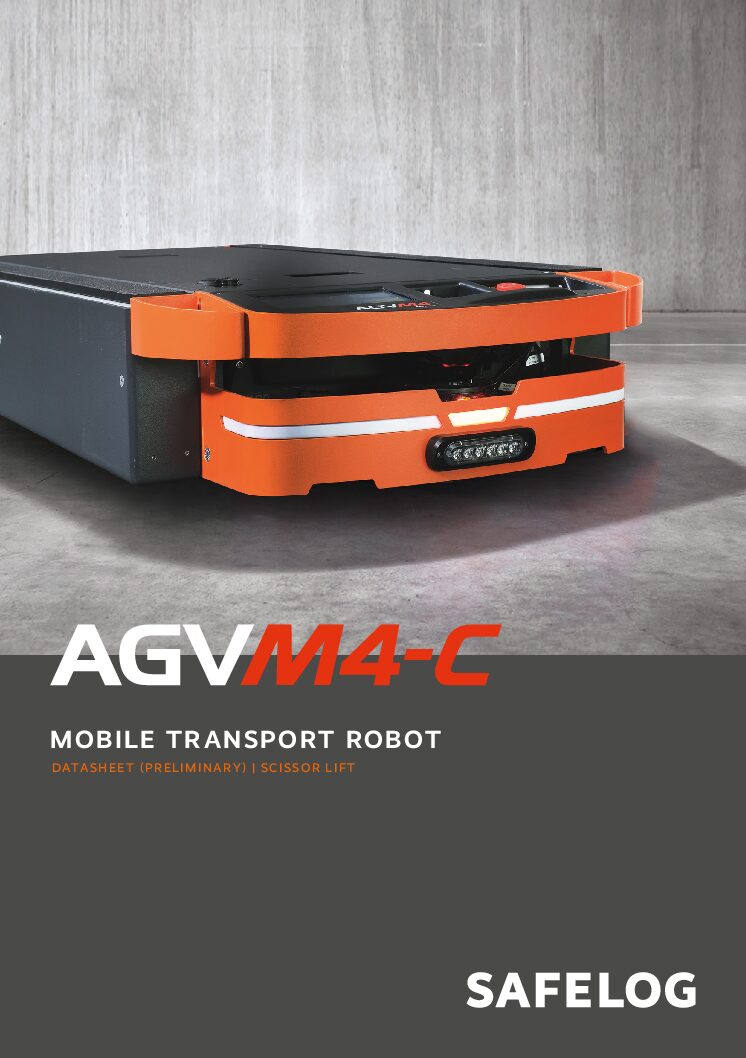

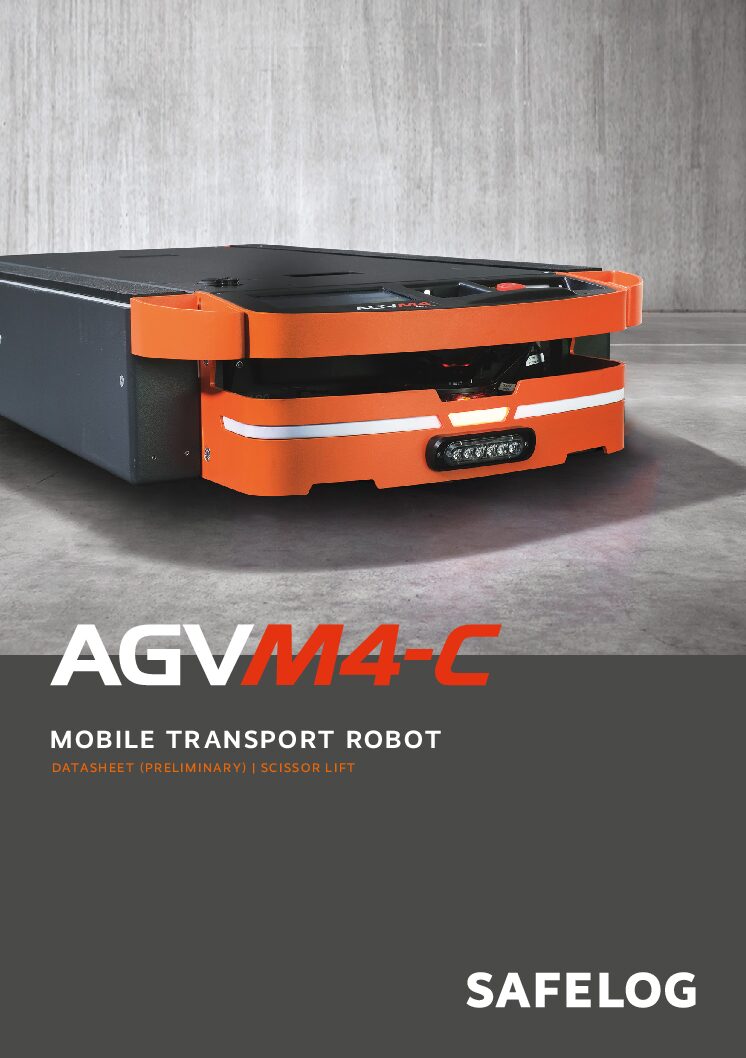

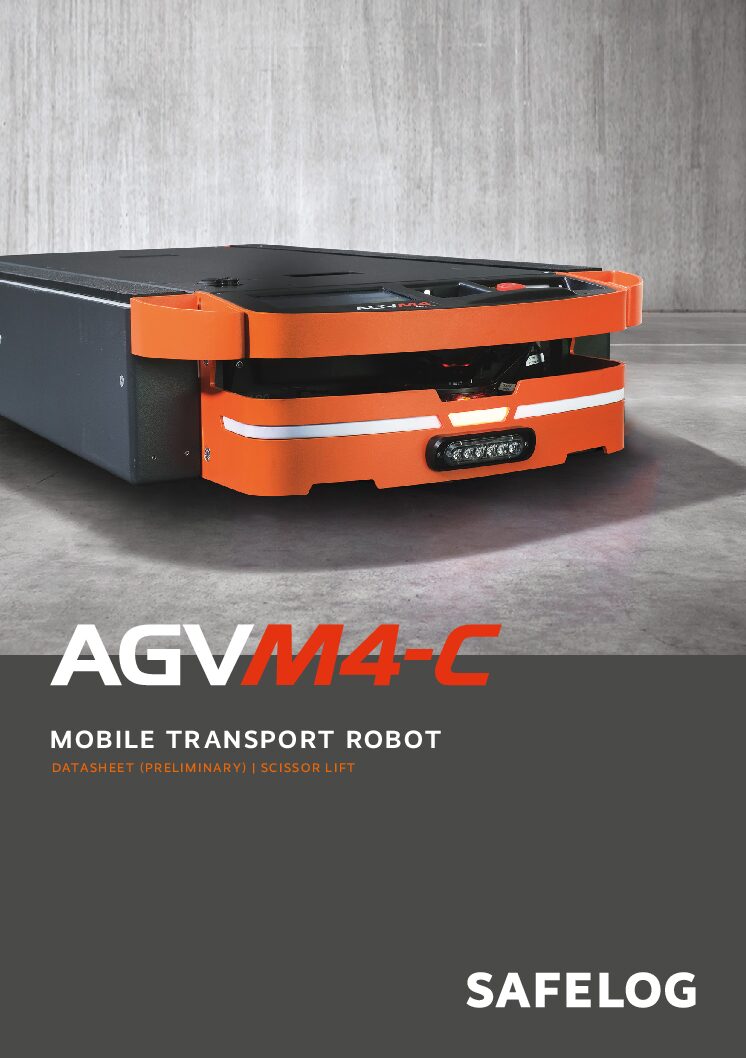

Due to the lifting mechanism, the AGV M4-C, at 600 mm, is 150 mm wider than its sister model. The low unit height of 220 mm enables it to drive under all standard racks, pallets and load carriers. The lifting height of the scissor lift system is 40 mm. The lifting rails running along the entire chassis provide a more even load distribution on the mobile transport robot than lifting mechanisms acting at specific points. This results in more stable load storage on the unit. The maximum topload is 1,000 kg.

DIMENSIONS:

1460 / 600 / 220 (L/W/H) in mm

TARE WEIGHT:

305 kg

SPEED:

from 0.02 up to 1.6 m/s

BATTERY CHARGING:

in-process charging using an inductive charging system

NAVIGATION: hybrid navigation using contour navigation, magnetic track, camera navigation and odometry

DISPLAY:

7“ touch display for ease of use

DIMENSIONS:

1460 / 600 / 220 (L/W/H) in mm

TARE WEIGHT:

305 kg

SPEED:

from 0.02 up to 1.6 m/s

BATTERY CHARGING:

in-process charging using an inductive charging system

NAVIGATION: hybrid navigation using contour navigation, magnetic track, camera navigation and odometry

DISPLAY:

7“ touch display for ease of use

DATA SHEET AGV M4-C (METRIC)

DATA SHEET AGV M4-C (IMPERIAL)

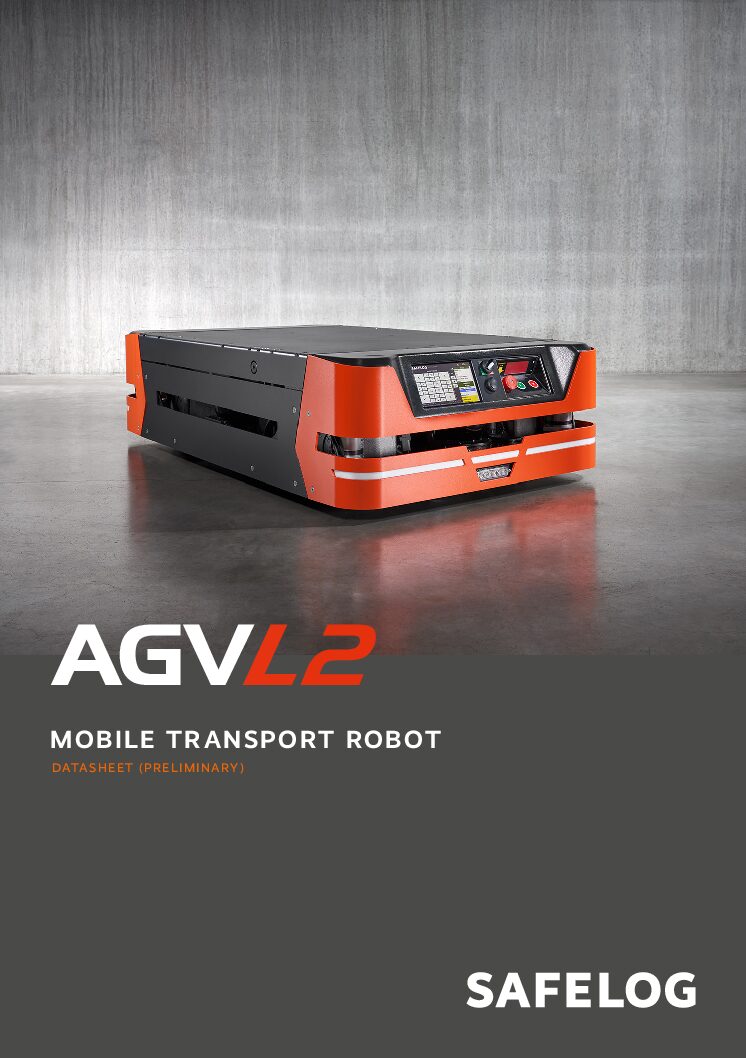

The mobile transport robot has a scissor-mounted lifting table that can pick up loads of up to 1,500 kg. Furthermore, the transport robot can handle tensile loads of up to 2,000 kg. The flexibility of the AGV has been further increased by reducing the unit height by 10 percent to 310 mm. The main focus of the application spectrum is on pallet and mesh box transports as well as goods-to-person processes. Furthermore, the AGV L2 is suitable as an assembly platform. The omnidirectional travel mode has been retained, as it guarantees high agility even in confined spaces. The drive of the new generation allows travel speeds between 0.02 m/s and 1.6 m/s. Communication with other SAFELOG robots and peripheral systems takes place via WLAN and the company’s own agent-based control software IntelliAgent.

DIMENSIONS:

1200 / 700 / 310 (L/W/H) in mm

TARE WEIGHT:

329 kg

SPEED:

up to 1.6 m/s

BATTERY CHARGING:

in-process charging using an inductive charging system

NAVIGATION: hybrid navigation

using contour navigation, magnetic track, camera navigation and odometry

DISPLAY:

7“ touch display for ease of use

DIMENSIONS:

1200 / 700 / 310 (L/W/H) in mm

TARE WEIGHT:

329 kg

SPEED:

up to 1.6 m/s

BATTERY CHARGING:

in-process charging using an inductive charging system

NAVIGATION: hybrid navigation

using contour navigation, magnetic track, camera navigation and odometry

DISPLAY:

7“ touch display for ease of use

DATA SHEET AGV L2 (METRIC)

DATA SHEET AGV L2 (IMPERIAL)

AGV-SOFTWARE

SAFELOG IntelliAgent –

process control without a control center

In stand-alone applications, SAFELOG AGVs handle transport processes to connect two or more loading and unloading points. The IntelliAgent takes care of the processing of the transport tasks. If several AGVs are used, the devices network over Wi-Fi to create a swarm intelligence. The swarm can include up to 1000 individual devices. The AGVs communicate with each other and receive orders through the IntelliAgent software, and the vehicles report their status to the swarm. Route planning and approval for sections of the route or intersections is done through all the devices communicating with each other. The swarm intelligence also monitors the charging of the individual devices to maintain optimal availability. IntelliAgent control software eliminates the need for a central control station and is compatible with other SAFELOG products. A connection to customer-specific PLCs is also possible. The software is 5G compatible.

SAFELOG AGV LIVE App (iPhone & iPad)

With the help of the SAFELOG AGV LIVE app, it is possible to call up the process data from an AGV on a mobile device. After installing the app on a smartphone or tablet, scan the QR code for the AGV to identify the vehicle in the app. Information about the software version and general details about the device, such as the current location or the last RFID tag passed, can then be called up. The app can also generate error messages or service requests. The ticket generated is sent directly to the SAFELOG service team and, if necessary, a spare parts order is triggered. The app is currently available for iPhone, iPad, iPod touch and Mac.

AGV-ACCESSORIES

Charging system

• Inductive charging system from Wiferion (built-in)

The Wiferion etaLINK 3000 is a patented inductive charging system for industrial electric vehicles and mobile robots. Since the systems do not require plug-in or sliding contacts, they enable interim charging of the batteries.

• SAFELOG charging system (built-in)

The energy unit on the AGV is charged during operation by the SAFELOG charging system using sliding contacts. For this purpose, charging contact plates are located in the area where the SAFELOG AGVs operate. These contact plates are wired to a 48V charging station to supply power. When the vehicle passes over and comes to a standstill above the charging contact plate, the energy storage units in the AGVs are charged by the sliding contacts. The charging contact plate has inclined contact surfaces to ensure low-wear connection with the spring-mounted sliding contacts.

• Mobile SAFELOG charging system

For flexible charging of its AGVs, SAFELOG offers a mobile charging station. The charger, which is mounted on rollers, is transported manually and connected to the AGV. Power is supplied by a 230V connector plug. Charging during operation is not possible. Due to its compact design, the mobile SAFELOG charging system can also be used in confined spaces.

MobiJack

(only AGV S2, AGV M4 & AGV M4-C)

The SAFELOG MobiJack is an ergonomic transport system for the AGV models AGV S2, AGV M4 and AGV M4-C manufactured by SAFELOG. It is mechanically coupled to the vehicles and is used for internal transport of these AGVs. It enables fast and safe movement of the AGVs regardless of the track and remaining charge. This makes it easy to add individual units to an ongoing process or remove them from it. The compact design of the SAFELOG MobiJack means it can be used in confined spaces. The MobiJack has four swivel castors that allow it to move freely in all directions.

Recovery system

(only AGV L1)

To lift the SAFELOG AGV L1, eyebolts can be attached to the four lifting columns of the vehicle. Four round slings with a length of 1.5 m and a load capacity of at least 1 ton are attached to these. The AGV can then be transported with the aid of a suitable hoist.

Standard attachments

SAFELOG AGVs can be equipped with special attachments to transport top loads. The attachments are optionally available with or without conveyor technology and are suitable, for example, for the transport of KLTs (Euro boxes). The AGV controls the conveyor system and supplies power to it.

Customized attachments

The SAFELOG team can develop special attachments on request for customer-specific processes.