SAFELOG Picking systems – simply clear, clearly simple

The SAFELOG IntelliCart smart picking cart uses signal technology to enable efficient multi-order picking processes. It is used in complex picking applications with high throughput and for the simultaneous implementation of a range of sub-processes. It enables the parallel processing of up to 40 orders.

The pick-by-light / put-to-light system ensures maximum picking performance while actively avoiding picking errors. In combination with a SAFELOG AGV it provides ergonomic relief for the worker and by using movement automation it speeds up processes by around 7 percent.

SAFELOG’s IntelliPick control software monitors all picking operations and interfaces with the warehouse management or ERP system. This means the software can update warehouse stocks in real time. It also makes it easier to create picking batches and strategies. An additional benefit is that orders can be amended during the process.

INTRALOGISTIC made by SAFELOG –

Integrated solutions from A to Z

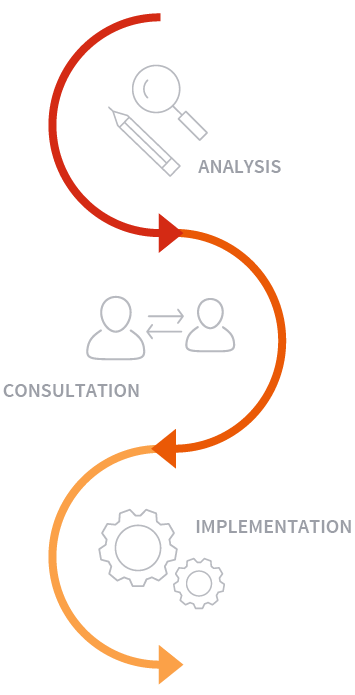

Analysis & Concept

An on-site appointment is the first step towards a customized intralogistics system. SAFELOG documents all the process steps and analyses the overall workflow to determine the potential for improvement. Based on this information, SAFELOG develops a tailor-made order picking concept.

Consultation & Planning

The results of the analysis are the foundation for the next steps. SAFELOG provides advice about suitable hardware and software and drafts an appropriate concept. The integration of the proposed SAFELOG components into existing ERP, production control or warehouse management systems is also taken into account. The goal is a well-thought-out integrated solution based on your needs.

Project planning & implementation

The modular structure of the SAFELOG intralogistics concept guarantees a wide range of different combinations. Based on the results of consultation and planning, SAFELOG implements the best possible solution for your needs. Assembly and commissioning are carried out by experienced SAFELOG service technicians.

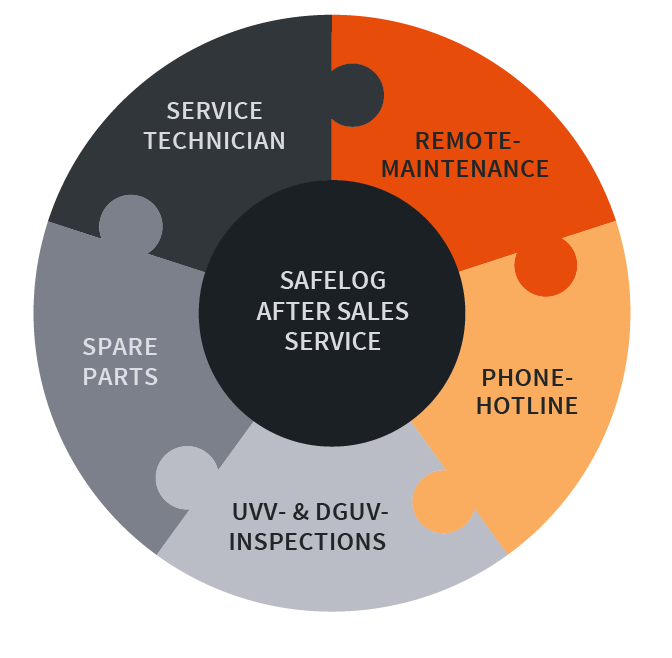

After Sales Service

For SAFELOG, commissioning is just the start of further cooperation. The smooth running of your processes is a priority for us, even after you sign off on the equipment. We are at your side as a reliable and flexible partner with a wide range of services. We will be delighted to answer any questions you may have about maintenance, service and repair.

SAFELOG Pick-by-Light / Put-to-Light

In accordance with the poka-yoke principle for preventing errors, the system immediately points out an error during order processing. Errors must be corrected to continue the picking process. For visualization, SAFELOG uses signal lamps and acknowledgement buttons in the form of ASi-5 compartment displays and ASi-5 eTag display modules.

The entire order procedure is displayed on an ASi-5 / ASi-3 MiniMaster Touch Display with 7″ monitor. A two-core profile cable is used for data transfer and power supply and serves as a connection to the control system. The SAFELOG software is also the interface to warehouse management or ERP systems. Among other things, this provides real-time stock reconciliation.

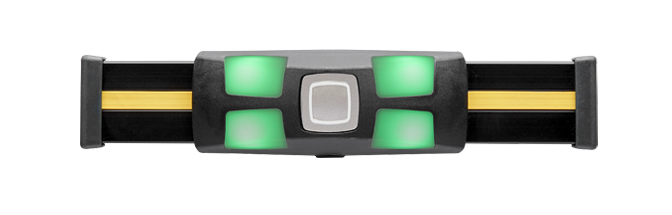

SAFELOG Pick Systems individual components

Depending on the model, each pick lamp has two or four eye-catching seven-color LED lights and a sensor or acknowledgement button. The ASi-5 eTag module is equipped with a 2.9″ e-ink display screen (pixel resolution 296 x 128). This displays product and compartment information or QR codes. After picking or putting the required quantity, the worker confirms it with the sensor or the acknowledgement button. The inventory is updated in real time. The components are mounted quickly and easily with a wireless click system using two-core ASi profile cable.

Technical details ASi-5 compartment displays:

- Easy installation due to cordless click system

- 4 seven-color LEDs for compartment display with acknowledgement button

- Faster data transfer using ASi-5 technology

- Interfaces to third-party components

Technical Details ASi-5 eTag Display Module:

- Easy installation due to wireless snap-on system

- 2 seven-color LEDs for compartment display with acknowledgement button

- Faster data transfer using ASi-5 technology

- Interfaces to third-party components

- 2.9″ E-Ink display to show item descriptions, quantities, barcodes and QR codes on eTag modules in black and white and red

The MiniMaster is a multifunctional tool that is responsible for operator registration, displaying the current order and controlling the compartment displays. The compact 7″ touch display shows the single- and multi-order picking tasks and manages their processing.

As a control instrument, the MiniMaster monitors the reported pick quantity based on the number of times the acknowledgement button is pressed. The compartments are displayed on ASi-5 compartment displays or ASi-5 display modules. The system has special functions such as correction or inventory processes. Thanks to data exchange based on ASi-Bus technology, the MiniMaster controls up to 96 participants. It functions as an interface to ERP or warehouse management systems. ASi-Bus technology ensures fast transmission of order data as well as real-time data transfer of all acknowledged orders to the host system.

Technical details MiniMaster:

- 7“ Touch-Display

- Faster data transfer using ASI-5 technology

- 4x USB & 1x Ethernet connection

- Controls up to 96 participants

- Compact dimensions 197.4 / 115.1 / 42.9 (in mm)

SAFELOG IntelliCart –

High performance multi-order picking

It is equipped with its own control software, which forms the interface to other SAFELOG products, to peripheral systems and to warehouse management / or ERP systems. By using the IntelliCart, nothing needs to be installed on the racking, all display components are part of the order picking trolley.

The software manages up to 40 different orders in parallel. The display for each pick is provided by an LED light strip as well as the MiniMaster display. A sensor monitors correct compartment access, so that the storage compartment is only displayed by means of Put to Light if it is correctly picked.

In addition to sensor monitoring, barcode scanners or push-buttons can be used for confirmation.

The connected AGV then pulls the IntelliCart to the next storage compartment. The picking cart can also be moved manually. After all of the orders have been successfully processed, the system automatically informs the worker and prompts their return to the base.

SAFELOG IntelliPick

SAFELOG IntelliPick software acts as an interface to warehouse management or ERP systems. It receives the order data and transmits all processed orders back to the host system in real time. The software controls all operations of a pick-by-light system and maps the complete picking process. This includes operator registration, every picking process and special functions such as corrections or inventory activities. Powerful ASi-Bus technology is used for data transmission.

Thanks to the modular structure of the SAFELOG IntelliPick software, it can be linked with a variety of data interfaces. The system is configured on the MiniMaster’s touch display. SAFELOG IntelliPick is compatible with numerous SAFELOG components and has several interfaces to third-party products.