Cost-effective fleet manager for SMEs

Already in December 2021, the TH Rosenheim started the research project FLEET in cooperation with our partner ScaliRo GmbH to develop an individually configurable fleet management system for driverless transport robots. This is also intended to offer small and medium-sized companies the possibility of automating work steps such as lifting, loading and unloading, and transporting workpieces cost-effectively using AGVs. The use of the VDA 5050 communication interface enables manufacturer-independent control of the mobile transport robots.

Implementation of the SAFELOG AGVs in 2 steps

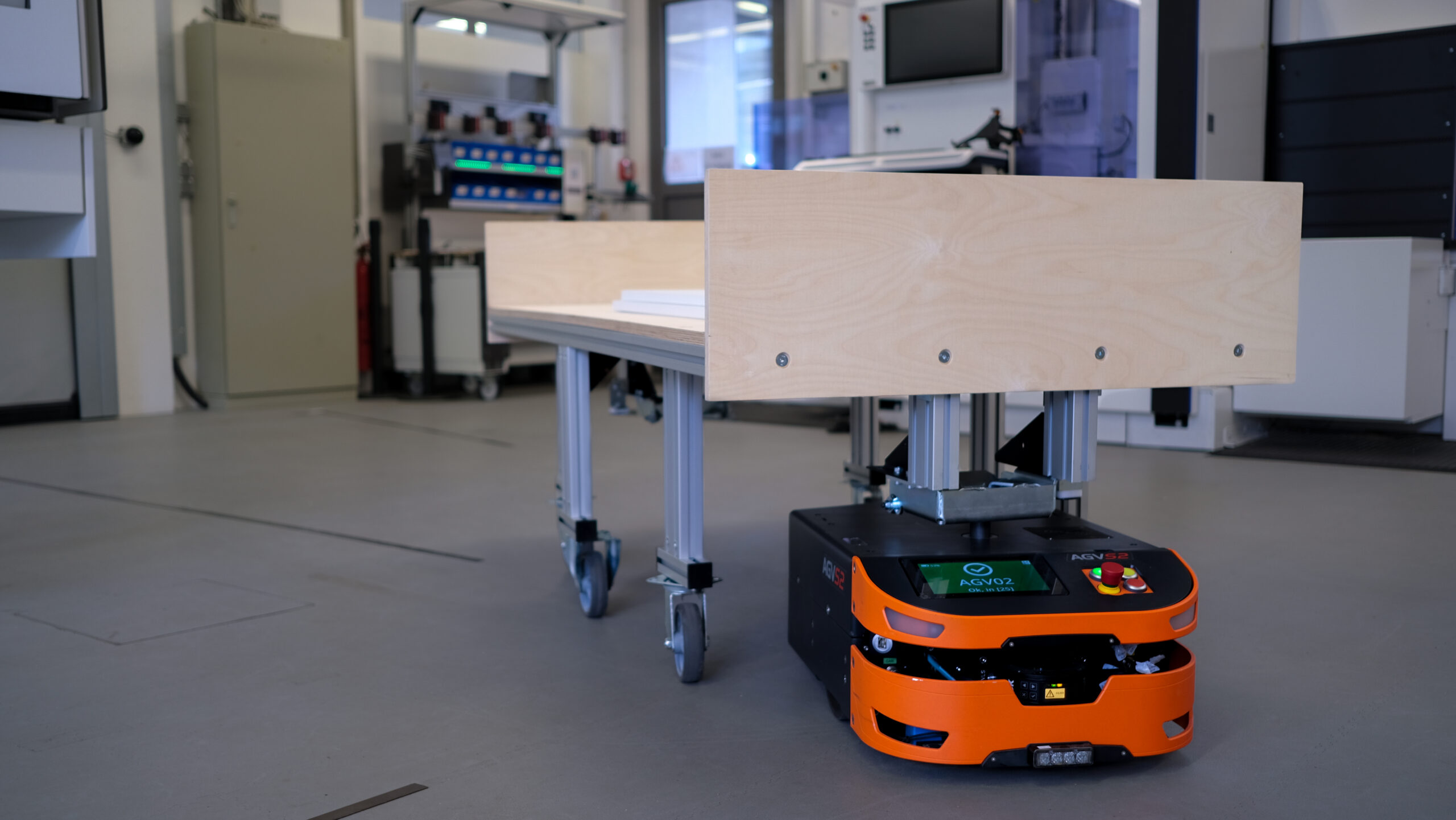

For the supply of workstations with small parts, the first SAFELOG AGV S2 was put into operation at the TH Rosenheim in May 2022. The proto_lab developed the use case for hardware picking. Via a special topload superstructure, the mobile transport robot functions as a supply vehicle for several workstations. By defining fixed stopping points such as “goods receipt”, “fittings warehouse” and “assembly station”, the AGV is requested via a terminal for the transport of fittings over predefined routes. In order to also explore and test the automation of flexible production processes with mobile transport robots in SMEs, the proto_lab team put a second SAFELOG AGV S2 into operation in January 2023. This mobile robot can transport larger components between the individual processing stations with the help of a specially developed trolley. Several production stations and waiting stations for the trolley are integrated in the test setup so that a continuous material flow and flexible linking of production processes can be mapped.

The two AGVs are controlled decentrally – directly via a touch display on the vehicle or at the production stations. Order placement is also possible via mobile devices. Due to the swarm intelligence of the AGVs, collisions are ruled out because the routes are pre-reserved by the mobile transport robots and a route segment can never be traveled simultaneously by both AGVs. As a result of the FLEET research project, the AGVs can now also be controlled with the individually configurable FleetEngine developed by our partner ScaliRo via the manufacturer-independent communication interface VDA 5050 V2.0. This software enables SMEs to integrate their special requirements independently for the first time without programming knowledge.

Four more AGVs for follow-up research project in the starting blocks

In a next step, the project will be further expanded by extending the process and integrating four additional SAFELOG AGVs. The expansion will take place in the course of the research project A-IQ ready, which explores the synergies of state-of-the-art quantum sensor technology, edge continuum orchestration of AI and distributed collaborative intelligence technologies based on use cases in different fields.

In addition to TH Rosenheim, our partner Scaliro is also on board. We are already looking forward to the commissioning of the additional mobile robots and are eagerly awaiting new insights from this exciting follow-up project.

More information about the proto_lab at TH Rosenheim: https://www.th-rosenheim.de/en/die-hochschule/labore/proto-lab

More information about the research project FLEET: (only in german): https://projekte.th-rosenheim.de/de/forschungsprojekt/799-fleet

More information about the research project A-IQ ready (only in german): https://projekte.th-rosenheim.de/de/forschungsprojekt/970-a-iq-ready

Contact

For further information please contact

marketing@safelog.de

Complimentary copy requested.